Tow

Hemp is sown at the end of April, in humid weather, in moist, clayey soil covered with a thick layer of humus, a material resulting from the decomposition of plant debris. There are two harvesting periods for hemp, as it is a dioecious plant ( the male and female flowers are on different plants). Thus, the female stems that carry the seeds mature later than the male stems. Once the hemp has been harvested, it is tied into small bales that are bundled together.

Hemp is sown at the end of April, in humid weather, in moist, clayey soil covered with a thick layer of humus, a material resulting from the decomposition of plant debris. There are two harvesting periods for hemp, as it is a dioecious plant ( the male and female flowers are on different plants). Thus, the female stems that carry the seeds mature later than the male stems. Once the hemp has been harvested, it is tied into small bales that are bundled together.

The textile fibres are contained in the hemp stalk; the cross-section of the hemp plant displays from the outside inwards: the epidermis, the cortical parenchyma, the pericycle formed by a thin-walled parenchyma in which the bundles of textile fibres are embedded, the bast and finally the wood. To isolate these fibres, the stems are subjected to a specific treatment: retting. This technique dissolves the gum-resinous material that binds the fibres together. It can be done either with running water, immediately after harvesting, or on dry straw with stagnant water, however, this second method results in a lower quality fibre. The retting can also be done using a bacteriological or chemical method. After the retting, a drying phase is carried out in the open air.

The textile fibres are contained in the hemp stalk; the cross-section of the hemp plant displays from the outside inwards: the epidermis, the cortical parenchyma, the pericycle formed by a thin-walled parenchyma in which the bundles of textile fibres are embedded, the bast and finally the wood. To isolate these fibres, the stems are subjected to a specific treatment: retting. This technique dissolves the gum-resinous material that binds the fibres together. It can be done either with running water, immediately after harvesting, or on dry straw with stagnant water, however, this second method results in a lower quality fibre. The retting can also be done using a bacteriological or chemical method. After the retting, a drying phase is carried out in the open air.

The scutching process aims to separate the straw and wood from the fibres. Although retting has eliminated the gum-resinous material, it has not destroyed the straw, which must be removed by a mechanical treatment including grinding and scutching. The product obtained following these treatments is the tow.

The scutching process aims to separate the straw and wood from the fibres. Although retting has eliminated the gum-resinous material, it has not destroyed the straw, which must be removed by a mechanical treatment including grinding and scutching. The product obtained following these treatments is the tow.

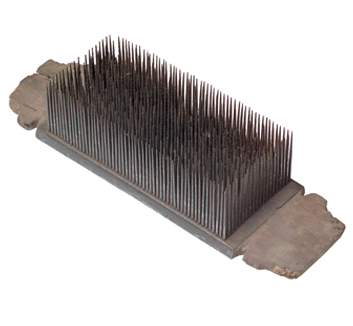

The still impure tow is combed; the finest is used in spinning and the threads obtained are used to weave a wide variety of articles (dish towels, household linen) either pure or in combination with cotton, linen or wool threads. Moreover, a fabric made of hemp and wool called melotin was manufactured in Chauvigny.

The still impure tow is combed; the finest is used in spinning and the threads obtained are used to weave a wide variety of articles (dish towels, household linen) either pure or in combination with cotton, linen or wool threads. Moreover, a fabric made of hemp and wool called melotin was manufactured in Chauvigny.

The most ordinary qualities give larger threads, used for the weaving of large sailcloths, tarpaulins or prelarts ( a fabric painted, tarred or waxed to be waterproof)..

Old rope and tow waste, called shives, can be reused in the paper industry to make fine, very strong paper. The waste, or oakum, from the scutching process is used for upholstery or caulking; the seeds are pressed into a drying oil that is used in paints and soaps, while the oilcake from the pressing of the seeds is used as fertiliser or animal feed.

Old rope and tow waste, called shives, can be reused in the paper industry to make fine, very strong paper. The waste, or oakum, from the scutching process is used for upholstery or caulking; the seeds are pressed into a drying oil that is used in paints and soaps, while the oilcake from the pressing of the seeds is used as fertiliser or animal feed.